Leak Detection System (ISA-SOU)

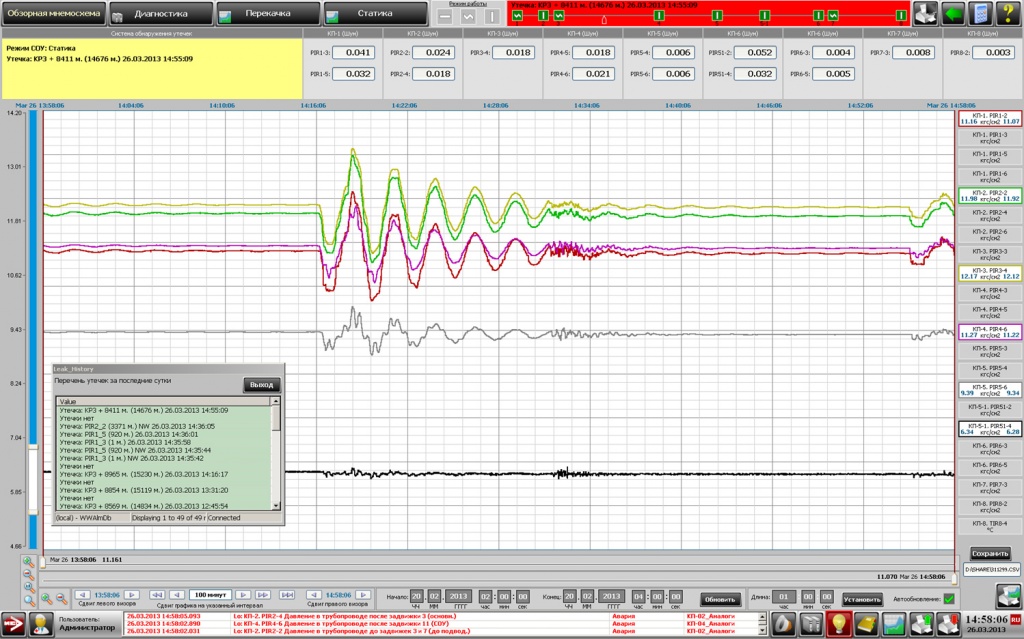

- Detection of pipeline tightness failure on the basis of flow rate, pressure and temperature values in dynamic and static mode of oil pipeline operation in less than 2 minutes after start of the leakage

- Calculation of place of leakage with accuracy of ±300 meters (when pressure sensors polling cycle is not more than 100 ms)

- Calculation of estimated leakage volume

- Registration of time of leakage detection

- Calculation of pig passage schedule

- Metering channel unreliability testing

- Backup of current and calculated information in database

- Export of data about leakage characteristics to related systems

- Identification of oil pipeline operation mode (stationary, non-stationary, static)

- Notification of operator about change of mode

ISA-SOU has been developed considering the best world practices of leading manufacturers of leak detection systems and in accordance with requirements of Russian and international standards.

Leak detection system includes server and controller software. Server software is installed on LDS server or LDS workstation, controller software is installed on LSD control stations or supplied complete with remote control system ISA-PIPELINE-TM developed by Insist Avtomatika. Remote control systems delivered by third parties can be used as well. ISA-SOU can use existing instrumentation installed on customer’s pipeline.

According to the API 1130 classification ISA-SOU can be considered a leak detection system based on statistical analysis and mathematic model. According to the classification RD 13.320.00-КТН-544-06 it can be considered as a combined LDS.

- Approach based on oil pipeline hydrodynamic model

- Underpressure wave estimation method

- Adjusted mass balance method

- Differential pressure estimation method (flowrate-pressure relationship or gradient method)

- Leak detection method for static mode

- Calculation of oil/oil product mass in pipeline

- Estimation of oil product location in pipeline, calculation of batch volume length in symmetrical concentration limits

- Estimation of system pump-pipeline operating point

- Estimation of gravity-flowing sections in pipeline

- Estimation of volume/mass of oil/oil product in gravity-flowing sections

- Forecasting of time for tank emptying/ filling

- Estimation of oil/oil product in the absence of flow meters